- Folder Product Stability and Shelf Life Evaluation

- Views 2486

- Last Updated 27/05/2022

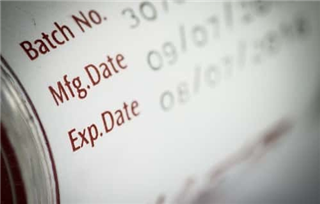

Today, consumers are increasingly demanding food quality and expect that it will be maintained at a high level of quality during consumption. Shelf life is an important attribute of all foods, including raw materials, processed ingredients, and products. It is defined as the length of time that a product (1) remains to be safe; (2) remains the desired sensory properties, chemical, physical and microbiological characteristics; (3) complies with any nutritional data label statements; and (4) are accepted by consumers (Earle and Earle, 2008).

Food products can be classified into three categories as follows:

(1) Highly perishable foods (milk, meat, fresh fruits, and vegetables) - These products have a very short shelf life due to microbiological and/or enzymatic degradation. Measurements are taken daily to determine shelf life.

(2) Perishable foods (pasteurized milk, smoked meats, cheeses, and some bakery products) - These products with a short to medium shelf life may contain natural inhibitors or be processed for preservation. Measurements are taken weekly to determine shelf life.

(3) Highly stable foods (dry foods, canned foods, and frozen foods) - These products with a medium to long shelf life have undergone heat treatment or are maintained under specific storage conditions. Measurements are taken weekly or monthly to determine shelf life.

The effects on the shelf life of a product can be classified into compositional and environmental factors. Compositional factors are the characteristics of a product including ingredients; water activity (aw); pH value; total acidity; acid type; redox potential (Eh); available oxygen content, nutrients, natural microbiota, and microbial population; the natural biochemistry of the product formulation (enzymes, chemical reagents); preservatives (eg, salt content); and concentrations of reactants, inhibitors, and catalysts.

The environmental factors are what a product may be encountered as it moves through the food chain including time and temperature during processing; pressure in the vapor space; temperature control during storage and distribution; relative humidity (RH) during storage and distribution; exposure to light (UV and IR) during storage and distribution; the number of environmental microorganisms during processing, storage and distribution; atmospheric composition in the packaging; subsequent heat treatment (eg, reheating or cooking before using); and the distribution, retail and as well as consumption.

It requires basic food science and technology including food processing, food analysis, food packaging, and statistical techniques to evaluate the shelf life of a product. Shelf-life studies are performed on the products which are properly prepared, packaged and stored, ready for purchase and consumption (Steele, 2004). The shelf life can be determined based on (1) the relevant food laws; (2) instructions issued by the enforcement agency; (3) instructions provided by independent professional institutes; (4) current good manufacturing practices; (5) self-imposed endpoint evaluation; and (6) market information.